Robotics has evolved at an extraordinary pace, far beyond the limits once imagined by early pioneers. In the modern world, robots are no longer confined to the realm of science fiction. They have seamlessly integrated into industries ranging from manufacturing to healthcare, retail, and logistics. With the rapid advancement of technologies such as artificial intelligence (AI), machine learning (ML), and automation, the future of robotics holds even more exciting possibilities.

The role of robots in transforming industries is not just about replacing manual labor; it’s about enhancing productivity, improving efficiency, and even creating new opportunities for innovation.

Understanding Robotics: A Brief Overview

At its core, robotics involves the design, construction, and operation of robots. Robots are programmable machines capable of carrying out tasks autonomously or semi-autonomously. They are designed to replicate human actions, often with higher precision, speed, and consistency. Today’s robots come in various forms, from industrial robots in factories to surgical robots in hospitals and autonomous robots in warehouses.

The future of robotics is heavily intertwined with artificial intelligence (AI) and machine learning (ML), which allow robots to adapt to their environments, make decisions in real-time, and perform tasks that were previously impossible for machines. These advances are powering the next wave of automation across industries, pushing robotics to the forefront of technological innovation.

How Robotics is Transforming Industries

1. Manufacturing and Automation

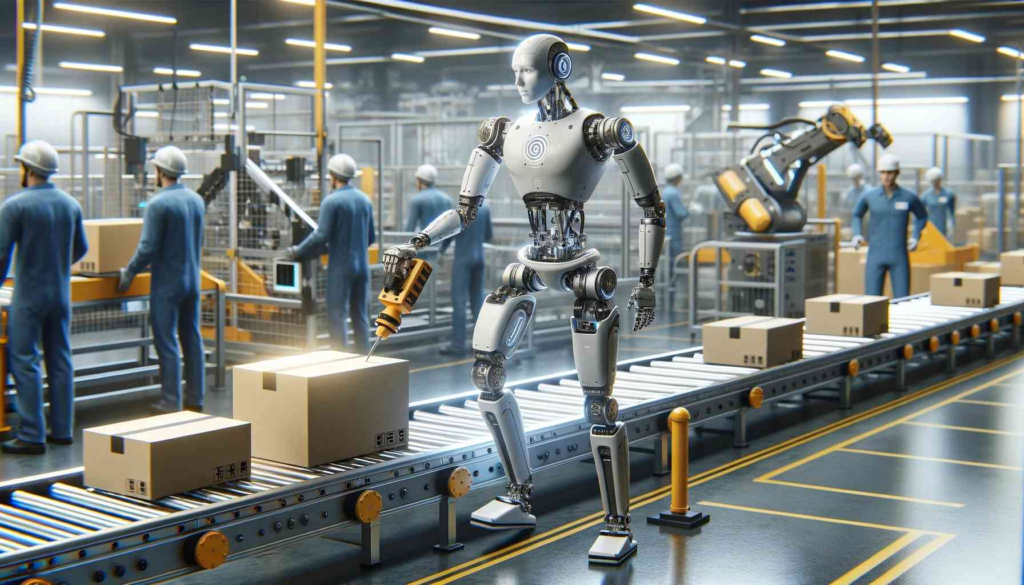

Robots have been a key component of industrial manufacturing for decades. The introduction of robotic arms and automated production lines revolutionized mass production, making it faster, safer, and more cost-efficient. However, the future of robotics in manufacturing is even more transformative.

- Collaborative Robots (Cobots): Cobots are designed to work alongside human operators, enhancing safety and productivity without replacing human workers. These robots assist in tasks such as lifting, assembly, and quality control.

- Example: In automotive manufacturing, cobots are helping workers assemble car parts more quickly and accurately. They handle repetitive tasks, reducing human error and fatigue.

- Precision Manufacturing: Robots are increasingly used for intricate manufacturing processes, such as in electronics or medical device production, where high precision is essential.

- Example: Robotics is critical in creating microchips and delicate components for electronics. Robots can perform tasks like placing tiny components on a circuit board with high accuracy, something that would be difficult for humans.

- Predictive Maintenance: Robotics combined with AI allows machines to monitor and predict failures in manufacturing equipment. This predictive capability reduces downtime and minimizes costs.

2. Healthcare and Surgery

Robotics is having a profound impact on the healthcare industry, especially in surgery and patient care.

- Surgical Robots: Surgical robots, such as the da Vinci Surgical System, allow surgeons to perform minimally invasive procedures with higher precision. These robots can perform tasks such as cutting, stitching, and cauterizing with greater accuracy than a human hand.

- Benefits: They reduce the risk of infection, minimize patient recovery times, and offer improved outcomes in complex surgeries.

- Robots in Elderly Care: With an aging population globally, robots are playing an increasingly important role in elderly care. Robots can assist in tasks like monitoring patients’ health, delivering medication, or even providing companionship.

- Example: In Japan, robots like Pepper are being used to provide emotional support to the elderly, offering reminders for medication and even engaging in conversation.

3. Logistics and Supply Chain Management

The logistics industry is experiencing a significant shift as robots are deployed to manage supply chains more efficiently.

- Autonomous Vehicles and Drones: Self-driving trucks, drones, and delivery robots are helping businesses streamline their delivery processes. These autonomous systems can operate 24/7, reducing delivery times and costs.

- Example: Companies like Amazon are utilizing autonomous robots in their fulfillment centers to transport products between stations, improving speed and efficiency.

- Robotic Warehouses: In warehouses, robots are used for sorting, picking, and packing products, often operating alongside human workers.

- Example: Kiva Systems, acquired by Amazon, developed robots that autonomously navigate through warehouses to deliver items to workers, significantly increasing operational efficiency.

4. Agriculture and Farming

Robotics is revolutionizing the agriculture industry by enhancing precision farming and improving crop management.

- Autonomous Tractors and Harvesters: Robotic tractors and harvesters are now capable of planting, irrigating, and harvesting crops autonomously. This increases efficiency and reduces labor costs, which are often high in agriculture.

- Example: Companies like John Deere are integrating AI and robotics into their machines, allowing for data-driven decisions in crop care and harvesting.

- Drones for Crop Monitoring: Drones equipped with sensors and cameras can monitor crop health, measure moisture levels, and identify areas that need attention.

- Benefit: This helps farmers make data-driven decisions, ultimately leading to more sustainable farming practices and higher yields.

5. Retail and Customer Service

Robots are becoming increasingly prevalent in retail environments, from customer service bots to inventory management systems.

- Self-Checkout Systems: Automated checkout systems are becoming common in retail stores, allowing customers to scan items and complete purchases without human assistance. Some stores have even begun using robots to scan shelves and identify products that need restocking.

- Example: Zara has employed robots in its stores to assist with inventory management, while Pepper robots are used in some stores to greet customers and provide assistance.

- Customer Service Chatbots: AI-powered chatbots are now used extensively in customer service across industries. They can handle a wide range of customer inquiries, reducing the need for human agents and improving response times.

- Example: Sephora uses an AI-driven chatbot that provides personalized beauty recommendations based on a customer’s preferences and purchase history.

6. Military and Defense

Robots are being used in military applications for tasks that are dangerous or difficult for human.

- Autonomous Vehicles: Unmanned aerial vehicles (UAVs), underwater drones, and autonomous ground vehicles are used for surveillance, reconnaissance, and logistical support, reducing the risk to human soldiers.

- Bomb Disposal Robots: Robots designed for bomb disposal can be deployed in hazardous environments to safely disarm explosive devices, saving lives and minimizing risks.

- Combat Robots: Although still in the early stages, combat robots are being tested for defense applications such as reconnaissance and, potentially, battlefield roles.

Also Read : The Future Of Machine Learning: Trends, Challenges, And Opportunities

Conclusion

The future of robotics is one filled with incredible potential to transform industries across the globe. As technology continues to advance, robots will become smarter, more capable, and more integrated into our daily lives. From improving the efficiency of manufacturing to enhancing patient care in healthcare, robots are reshaping industries in profound ways.

However, with these advancements come challenges, such as the need for a skilled workforce to operate and maintain robots, as well as ethical concerns about automation’s impact on jobs. As industries continue to embrace robotics, it will be essential to balance innovation with the social implications of this technology.

7 FAQs

What are the main types of robots used in industry?

The main types of robots include industrial robots (e.g., robotic arms), autonomous robots (e.g., drones), collaborative robots (cobots), and service robots (e.g., healthcare robots).

How do robots improve efficiency in manufacturing?

Robots increase efficiency by automating repetitive tasks, reducing errors, speeding up production cycles, and performing 24/7 without breaks.

Are robots replacing human workers?

While robots do replace some manual jobs, they also create new roles in robotics programming, maintenance, and AI development. They often work alongside humans to enhance productivity.

What role do robots play in healthcare?

Robots assist in surgeries, patient care, and diagnostic procedures. They improve precision in surgery and reduce the risk of human error, leading to better patient outcomes.

Can robots help solve labor shortages?

Yes, robots can help alleviate labor shortages, particularly in sectors such as agriculture, healthcare, and manufacturing, where they take over repetitive or dangerous tasks.

Are robots dangerous to human workers?

Modern robots are designed with safety features to protect human workers. Collaborative robots, for instance, are specifically built to work alongside humans without posing danger.

What are the ethical concerns surrounding robotics?

Ethical concerns include job displacement, privacy issues, and the potential misuse of robotics in warfare. Balancing technological advancement with ethical considerations is critical.